Principles of Heat Treatment

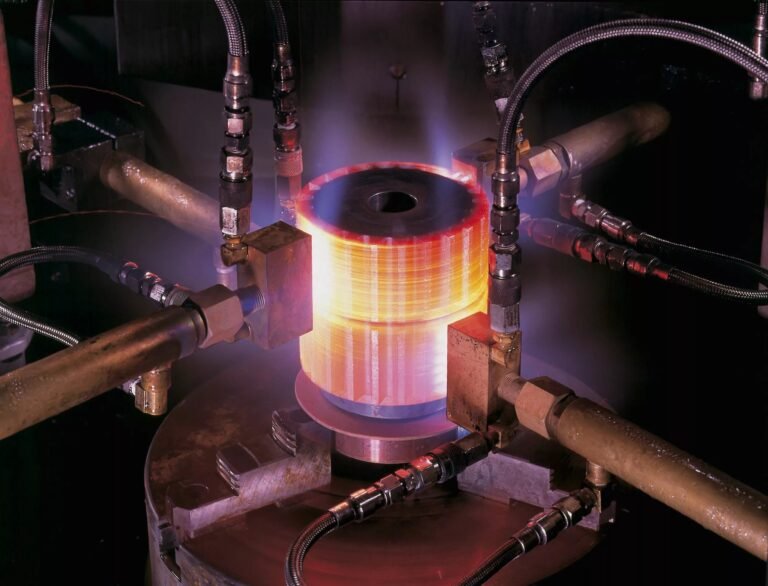

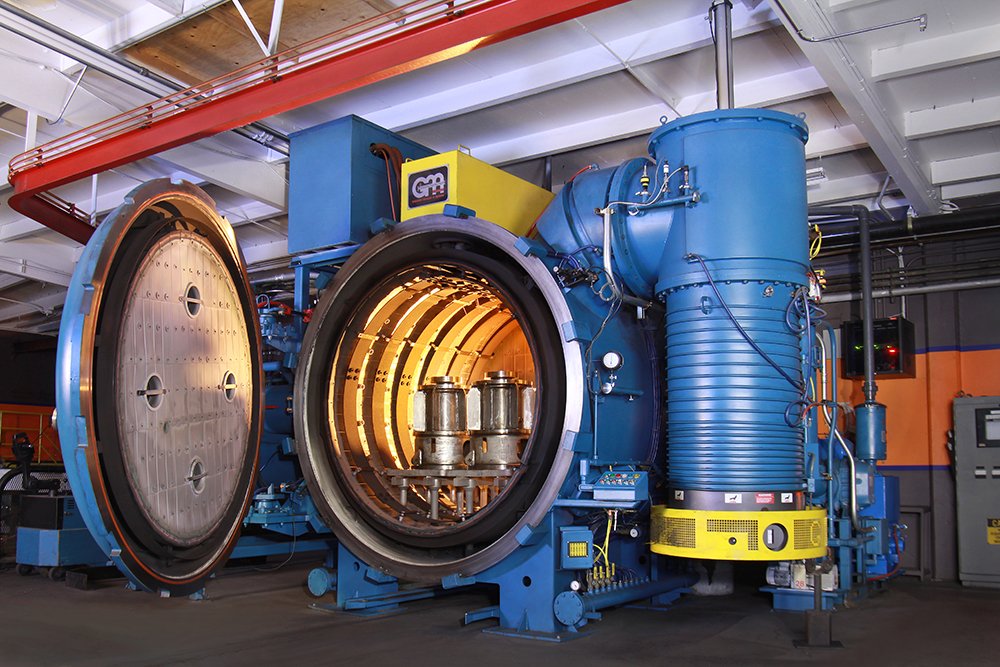

Steel heat treatment process is through the heating, holding and cooling methods to change the organizational structure of steel, in order to obtain the required properties of a workpiece heat treatment process.

In the heating and cooling process of the organization of the transformation law for the development of the correct heat treatment process provides a theoretical basis for the determination of the parameters of the heat treatment process must be made to meet the specific workpiece steel organization of the law of transformation to obtain the required performance.